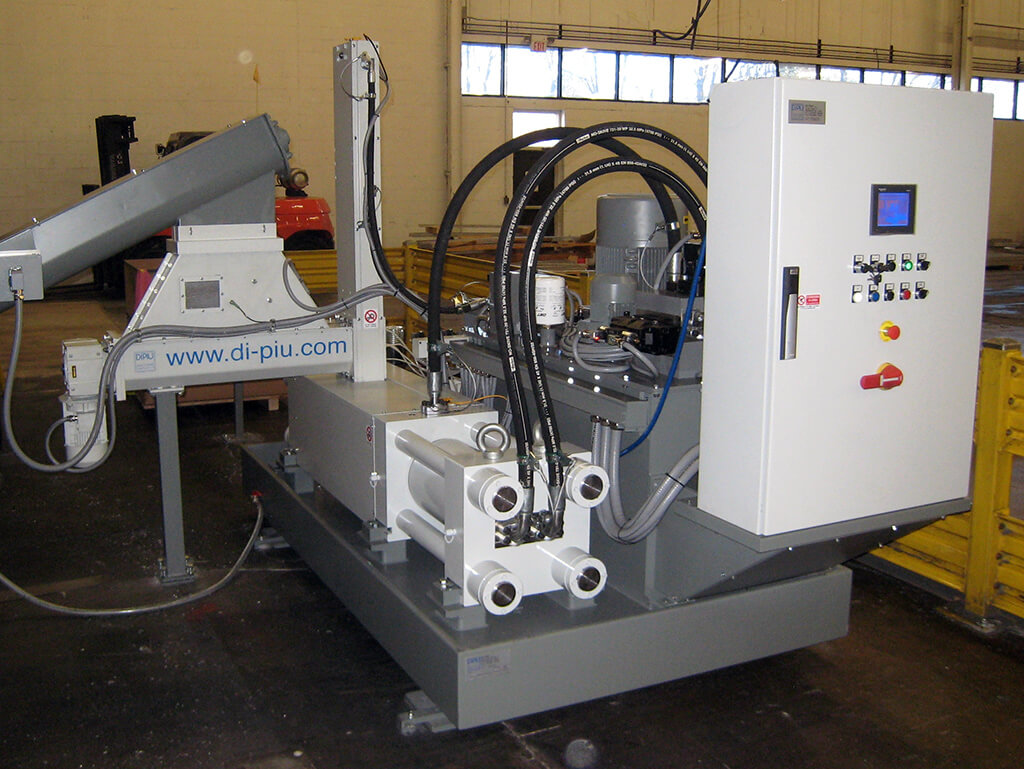

DI PIÙ METALBRIK series of hydraulic presses develop different densification pressures and are specifically designed to handle different metals, from aerospace aluminum, to copper and copper alloys like brass and bronze, to steel, cast iron, and even titanium. DI PIÙ METALBRIK are heavy duty hydraulic presses that employ the best available components. The hydraulics are made exclusively using Parker pumps and controls, for ease of maintenance and for part availability everywhere in the world.

A vast choice of preparation and handling equipment complements the METALBRIK presses. Loading hoppers, dumpster elevators, special grinders for turnings hanks, separators of solid metal from swarf, refiners, drag conveyors, augers. We offer all and any of these components. We can engineer a complete solution to handle and briquette your scrap metal swarf.

OUR LINE OF METAL CHIP PRESSES

| Metalbrik Series Specifications | HB220/70 | HB260/100 | HB 380/100 | |

| Output [*] | lb./hr | 220–1700 | 440–2200 | 880–4400 |

| Diameter | inch | 2–3/4 | 4 | 4 |

| Power | kW (HP) | 26 (35) | 36 (48) | 36 (48) |

| Weight | lb. | 11,000 | 13,200 | 15,400 |

[*] The output capacity varies with the metal density. The smaller number refers to light metals, while the larger number refers to the heaviest metals.